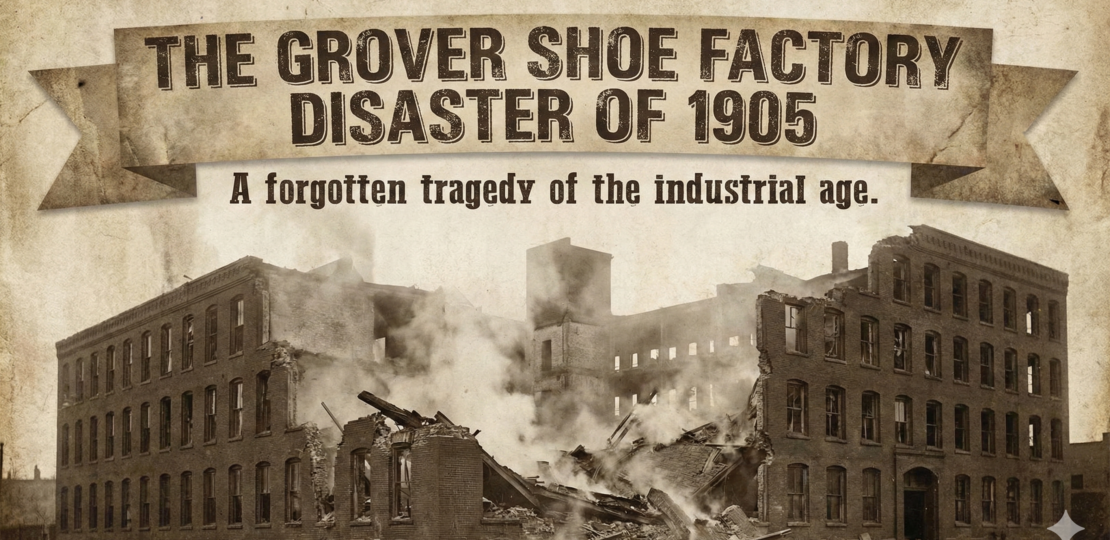

On a cold March afternoon in 1905, a steam boiler at the Grover Shoe Factory in Brockton, Massachusetts, ruptured without warning. The explosion tore through three floors, collapsed walls, and sent jagged iron hundreds of feet away. Fifty-eight workers were killed. There was no fire beforehand, no dramatic buildup—just stored energy released all at once. For engineers, this was the most unsettling kind of failure: silent, internal, and lethal.

At the time, boilers were everywhere—factories, ships, power plants—and they were treated as rugged workhorses. Inspection practices were inconsistent, design standards varied wildly, and safety devices were often improvised. The Grover boiler had been operating at low pressure and wasn’t even in use when it failed. That detail mattered. The explosion wasn’t caused by careless operation but by a hidden structural flaw and metal fatigue—failure accumulating invisibly over years.

The engineering lesson was brutal but clarifying. Materials remember their past. Repeated stress, corrosion, and poor fabrication leave signatures that don’t announce themselves until catastrophe. In response, engineers and policymakers pushed for something radical at the time: standardized codes. Within a few years, the American Society of Mechanical Engineers developed what became the ASME Boiler and Pressure Vessel Code, defining allowable stresses, material quality, inspection intervals, and safety margins.

This shifted engineering culture. Safety stopped being an afterthought and became a design parameter. Calculations had to assume uncertainty. Redundancy and inspection were no longer signs of mistrust in craftsmanship but acknowledgments of reality. The modern idea that an engineer is ethically responsible not just for performance but for human life hardened into place here.

The Grover disaster rarely appears in popular history, but it echoes every time a pressure vessel is stamped, inspected, and signed off today. Engineering progress isn’t only about building bigger and faster. Sometimes it’s about learning that invisible failures are the most dangerous—and deciding, collectively, never to ignore them again.

RELATED POSTS

View all